The corrugated roofing sheet roll forming machine is a production line that uses rolls to continuously form corrugated sheets. The line generally consists of several components, including decoiler, a rollforming machine, a cutting station, and optional stacking system or table.

Decoiler: This machine is hydraulic operated responsible for providing the raw material for the corrugated sheet.

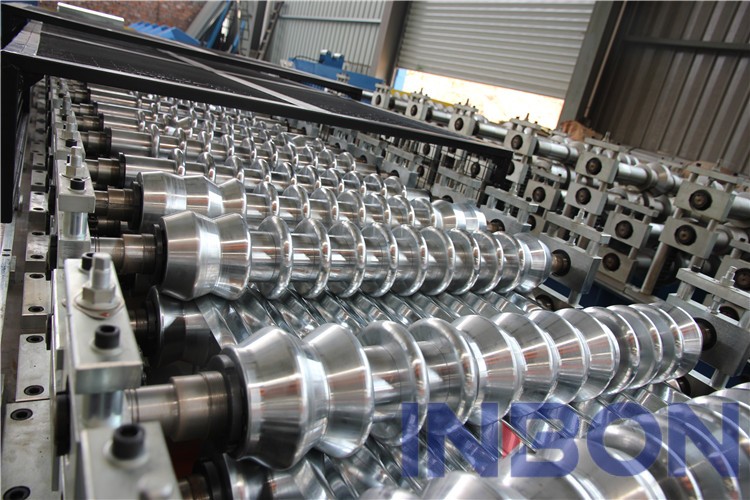

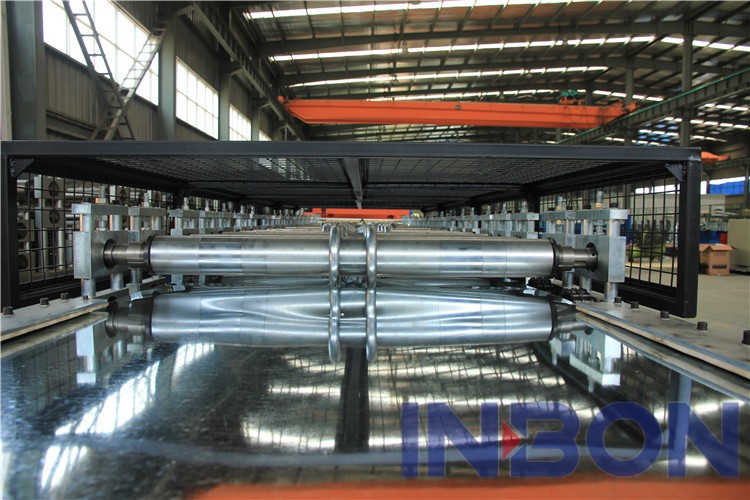

Corrugating roll forming machine: This is the heart of the roll forming process. The corrugator uses a series of rolls to flatten and form the corrugated pattern on the sheet. The rolls are specifically designed to create the desired corrugation pattern and size.

Cutting station: After the corrugation process is complete, the sheet is cut to the desired length. This station typically includes a saw or cutting blade that cuts through the sheet along the length.

Stacking system: The conveyor system is responsible for moving the formed corrugated sheet from one station to the next. It ensures that the sheet remains in place and aligned during the entire production process.

Roofing sheet roll forming machine speed and production capacity can be adjusted based on demand and product requirements.