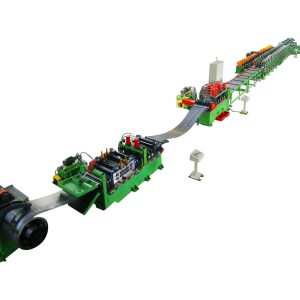

The flying shear custom made roll forming machine is a highly specialized and versatile piece of equipment designed for the production of a wide range of profiles. It combines the precision of a flying shear with the adaptability of a roll forming machine, enabling the production of complex, customized profiles with remarkable efficiency and precision.

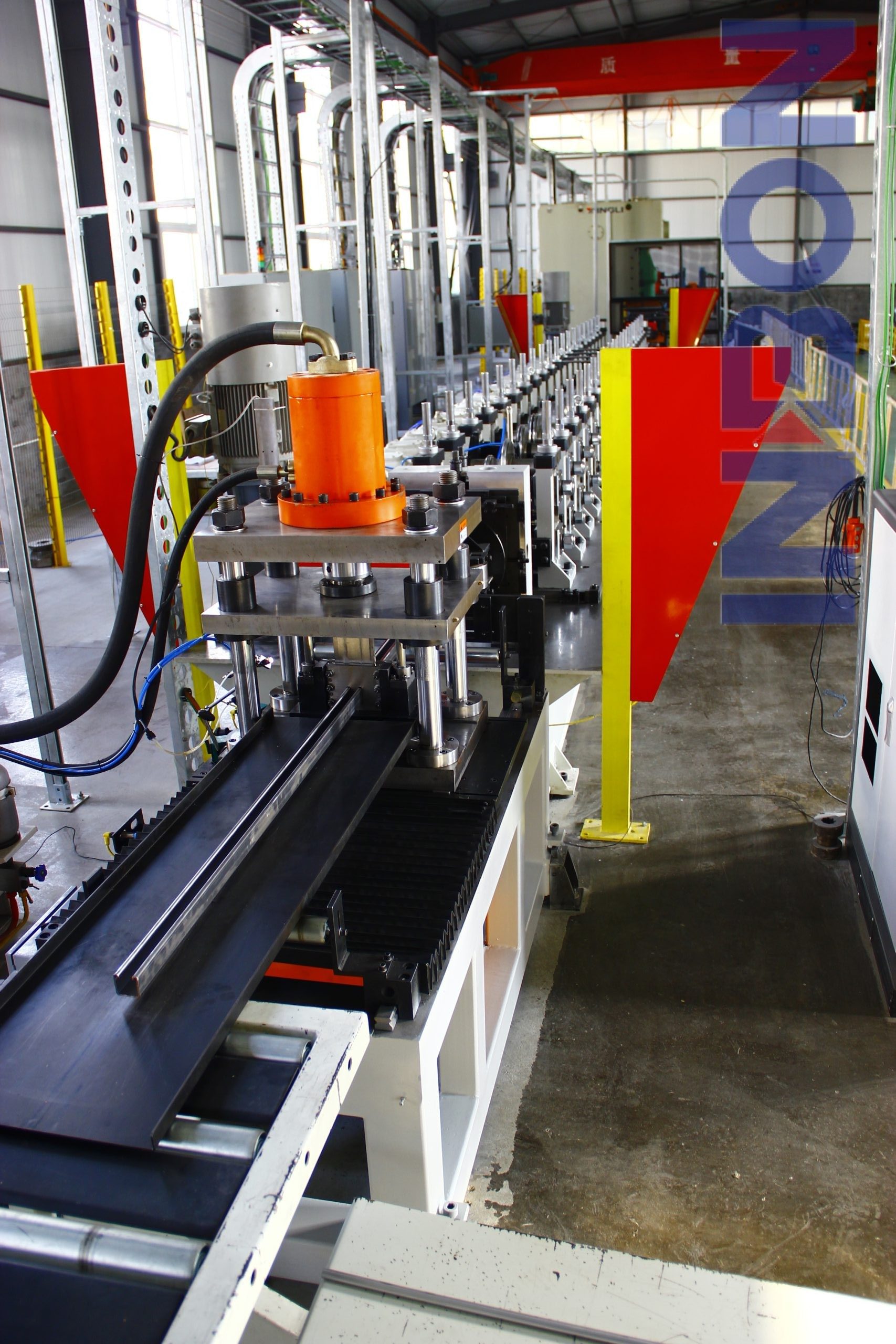

The flying shear section of this machine is tailored to handle the unique cutting requirements of each individual profile with incredible accuracy and speed. It features precision-engineered cut-off tool and advanced servo systems that allow for accurate and repeatable cutting of a wide range of sheet sizes, materials, and thicknesses.

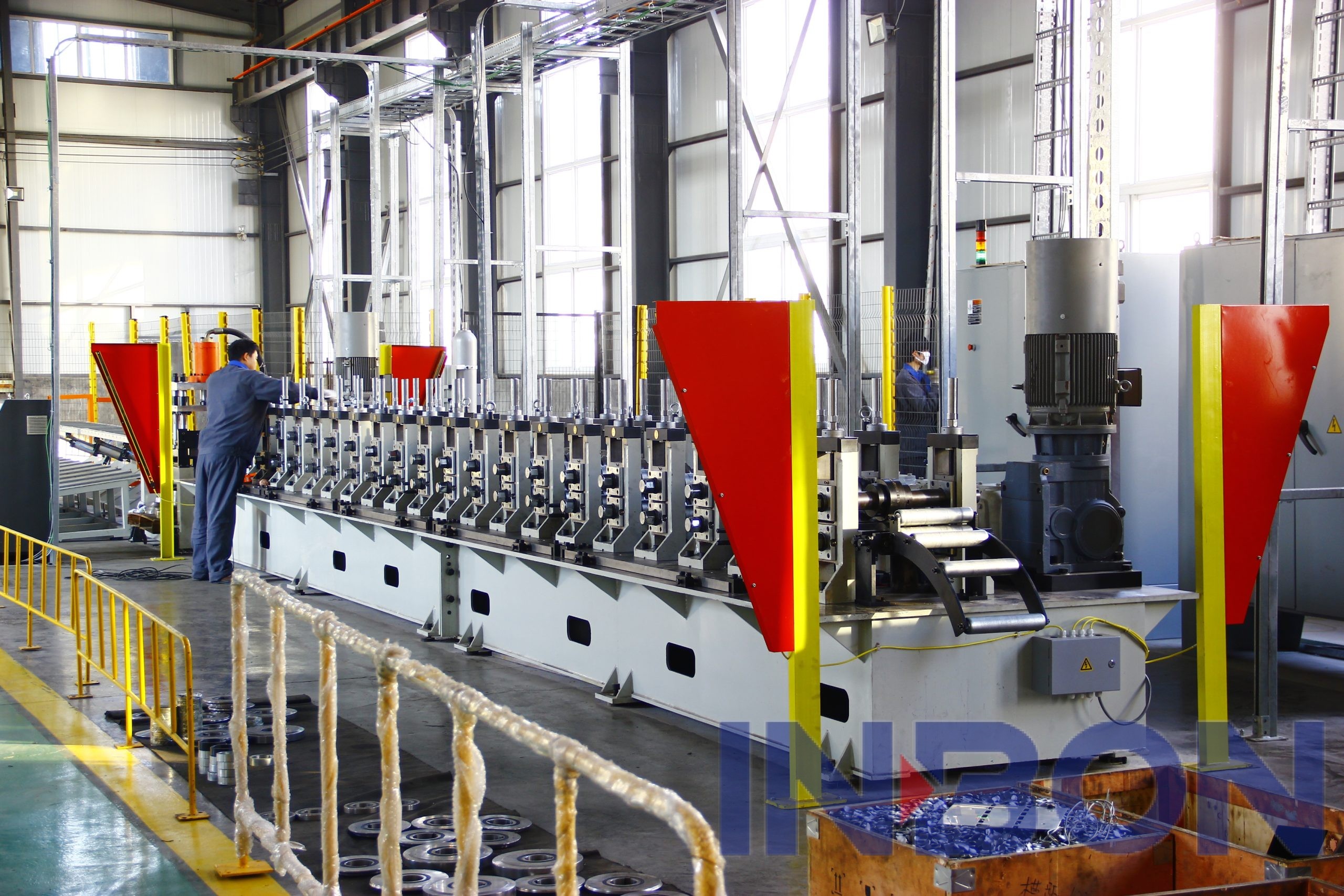

It consists of adjustable roll sets that can be configured to produce designed profiles. The rolls are precision-engineered and synchronized to provide uniform bending and ensure consistent shape quality across multiple production runs. This adaptability allows manufacturers to produce profiles that are tailored to specific applications or customer requirements.One of the key advantages of the flying shear custom made roll forming machine is its ability to handle a diverse range of profiles. Whether it’s for the construction industry, automotive sector, or any other industry that requires custom sheet metal components, this machine can produce them with unmatched precision and efficiency. It offers manufacturers the flexibility to produce small batches or large quantities of customized profiles without compromising on quality or efficiency.

Moreover, the flying shear custom made roll forming machine is designed for ease of operation and maintenance. It features user-friendly controls and intuitive operator interfaces that allow operators to quickly set up and run production with minimal training. The modular design also facilitates easy access to components for maintenance and troubleshooting, reducing downtime and operational costs.