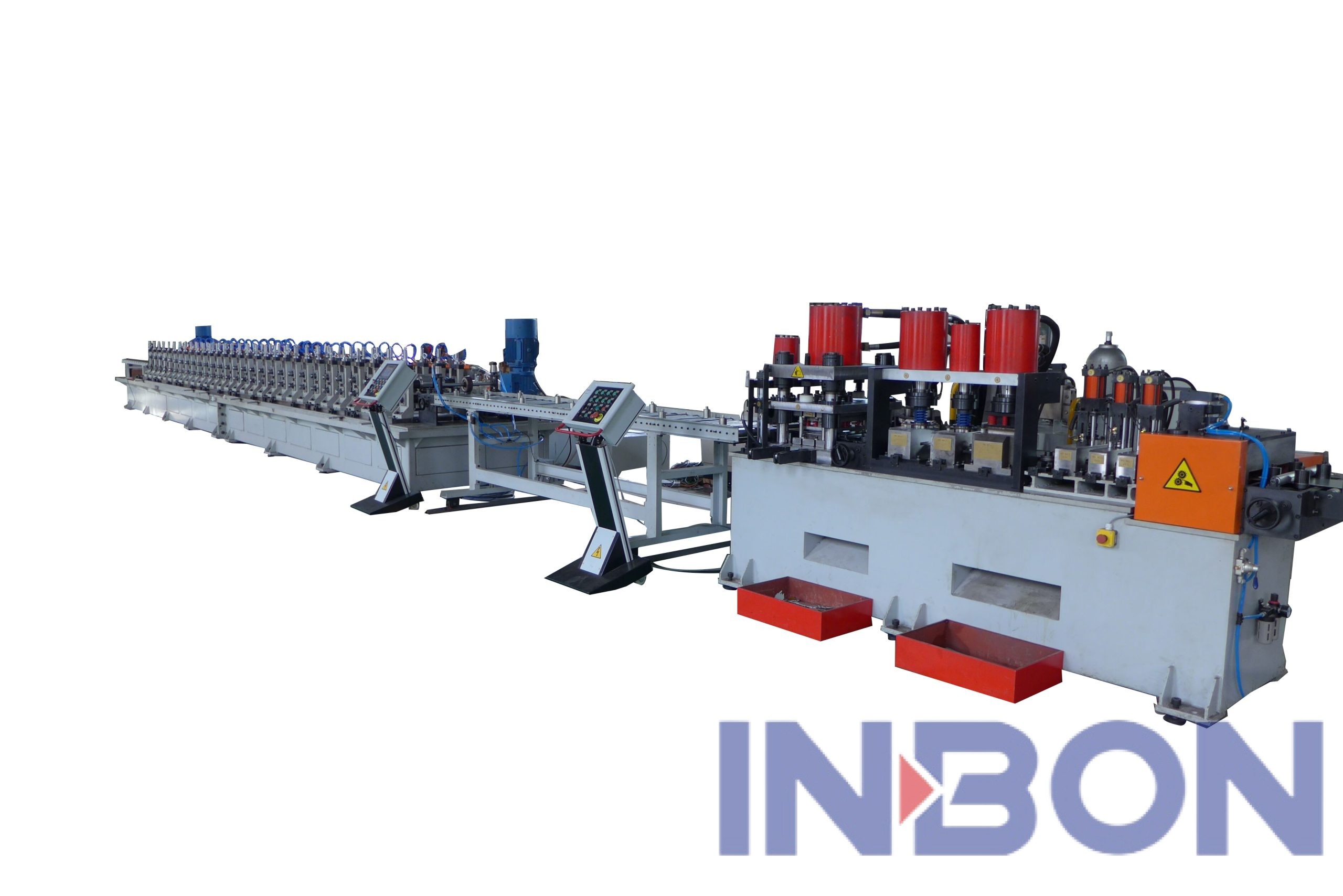

**Door Frame Roll Forming Machine: Precision in Construction**

In the realm of manufacturing, the door frame roll forming machine takes center stage as a specialized and indispensable tool for crafting precise and efficient door frames. This advanced piece of equipment plays a pivotal role in streamlining construction processes, offering a range of benefits that contribute to the quality and versatility of door frame production.

**1. Precision Profiling:**

At the heart of the door frame roll forming machine is its ability to produce door frames with remarkable precision. This machine excels at shaping a variety of profiles, accommodating both standard designs and customized configurations to meet specific architectural requirements. The result is a consistently accurate and high-quality product.

**2. Material Adaptability:**

Versatility is a key attribute of the door frame roll forming machine. It can seamlessly process different materials, including steel, aluminum, and other alloys. This adaptability allows manufacturers to choose materials based on factors such as strength, durability, and aesthetic preferences, expanding the range of applications for door frames.

**3. Streamlined Efficiency:**

Efficiency is paramount in the construction industry, and the door frame roll forming machine delivers by providing a continuous and streamlined production process. Automated features, such as material feeding and cutting mechanisms, enhance efficiency, enabling manufacturers to meet demanding project timelines without compromising on quality.

**4. Customization Flexibility:**

One of the standout features of this machine is its customization capabilities. Manufacturers can easily adjust settings for different door frame profiles, facilitating quick changeovers between designs. This flexibility empowers businesses to respond swiftly to evolving market demands and offer tailor-made solutions.

**5. Component Precision:**

A door frame is composed of various components, including the header, jambs, and sill. The door frame roll forming machine ensures that each of these components is precisely formed, contributing not only to the structural integrity of the door but also to its overall longevity and performance.

**6. Automation Advancements:**

Modern iterations of the door frame roll forming machine integrate advanced automation features. Automated processes, from material feeding to roll adjustments, minimize the margin of error and reduce the need for manual intervention. This leads to consistent and high-quality production while optimizing the use of resources.

**7. Applications Across Industries:**

The applications of door frames produced by this machine span a wide range of industries, including residential, commercial, and industrial construction. The versatility of the machine allows for the creation of door frames that not only provide structural support but also contribute to the aesthetic appeal of diverse architectural settings.

**8. Maintenance and Safety:**

To ensure the longevity and optimal performance of the machine, regular maintenance practices are essential. This includes tasks such as lubrication and inspection of rollers and cutting tools. Furthermore, adherence to safety protocols is crucial to creating a secure working environment for operators.

In conclusion, the door frame roll forming machine stands as a testament to the marriage of precision and efficiency in modern construction. As the demand for tailored and high-quality door frames continues to grow, this machine remains a cornerstone in the industry, shaping the future of architectural integration.