IBR type roofing sheet roll former: An Insight into its Operation and Advantages

Roofing panel roll forming machine is a crucial piece of equipment in the manufacturing process of roofing materials. It is used to transform flat sheets of material into specific shapes that are essential for roof construction. This machine automates the complex process of bending and shaping metal sheets, making it faster, more efficient, and cost-effective.

I. Introduction

Roofing panel roll forming machines are essential in the production of shaped metal roofing materials. These machines have a significant role in the construction industry, as they facilitate the production of consistent, high-quality roofing panels efficiently.

II. Machine Operation

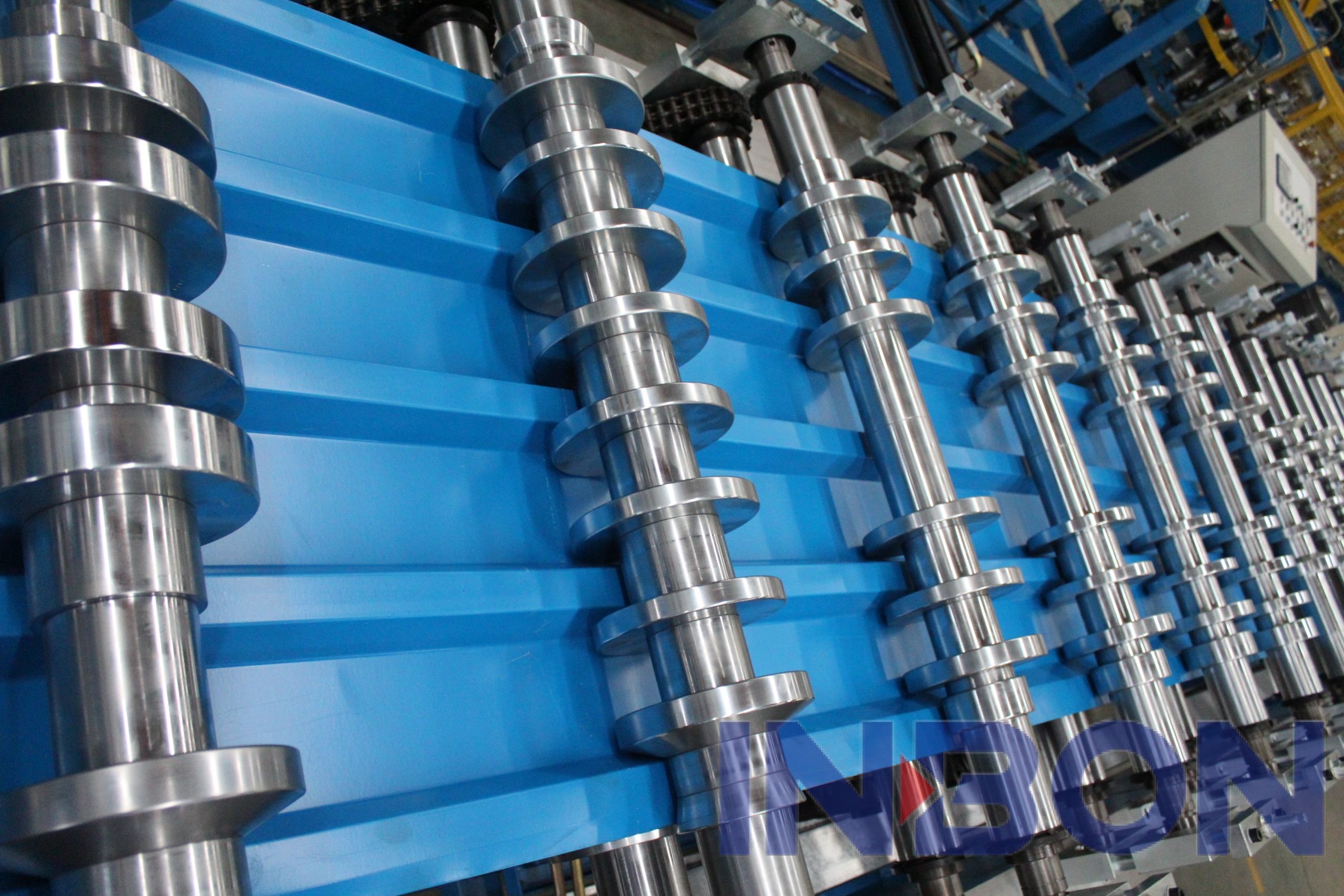

The roofing panel roll forming machine consists of decoiler, roll former, and cut-off press. these features are fully PLC controlled with automated production with only one man to set the parameters and to run without problem.

III. Advantages of Roofing Panel Roll Forming Machines

A. High production output: Roofing panel roll forming machines produce panels at a rapid rate, making them cost-effective for high-volume production.

B. Consistent quality: The precision engineering of these machines ensures consistent quality in the finished roofing panels.

C. Reduced labor: IBR type roofing sheet roll former automate the bending and shaping process, reducing the need for manual labor.