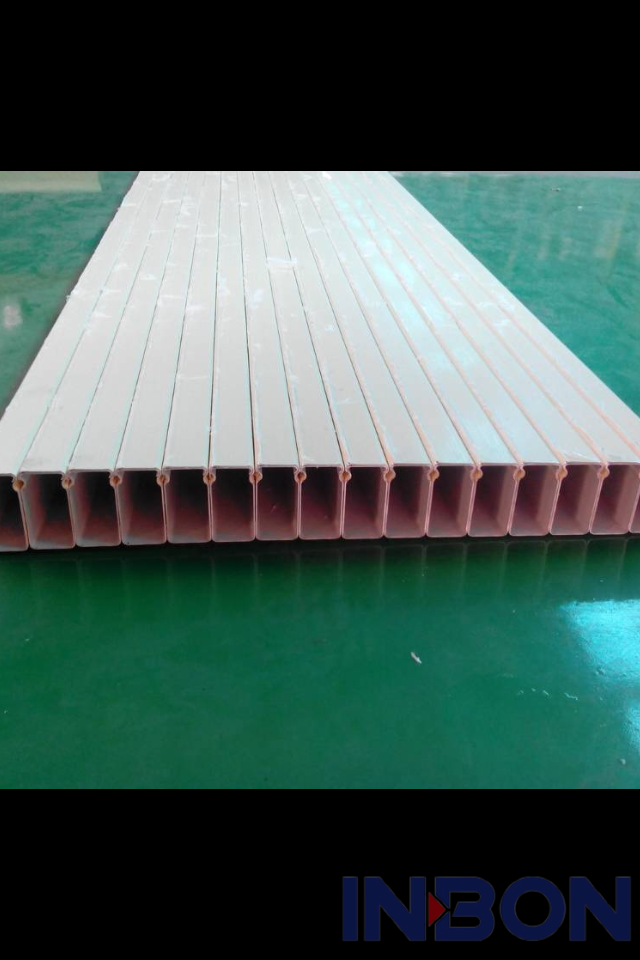

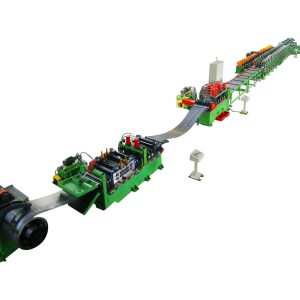

Sealed beam roll forming machine is a type of machine that uses rollers to shape and form sheet metal into specific shapes, such as channels, angles, and other profiles. The process involves passing the sheet metal through a series of rollers that apply pressure and bending forces to the material, creating the desired shape.

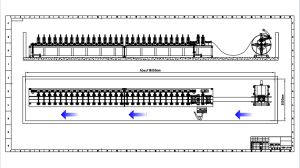

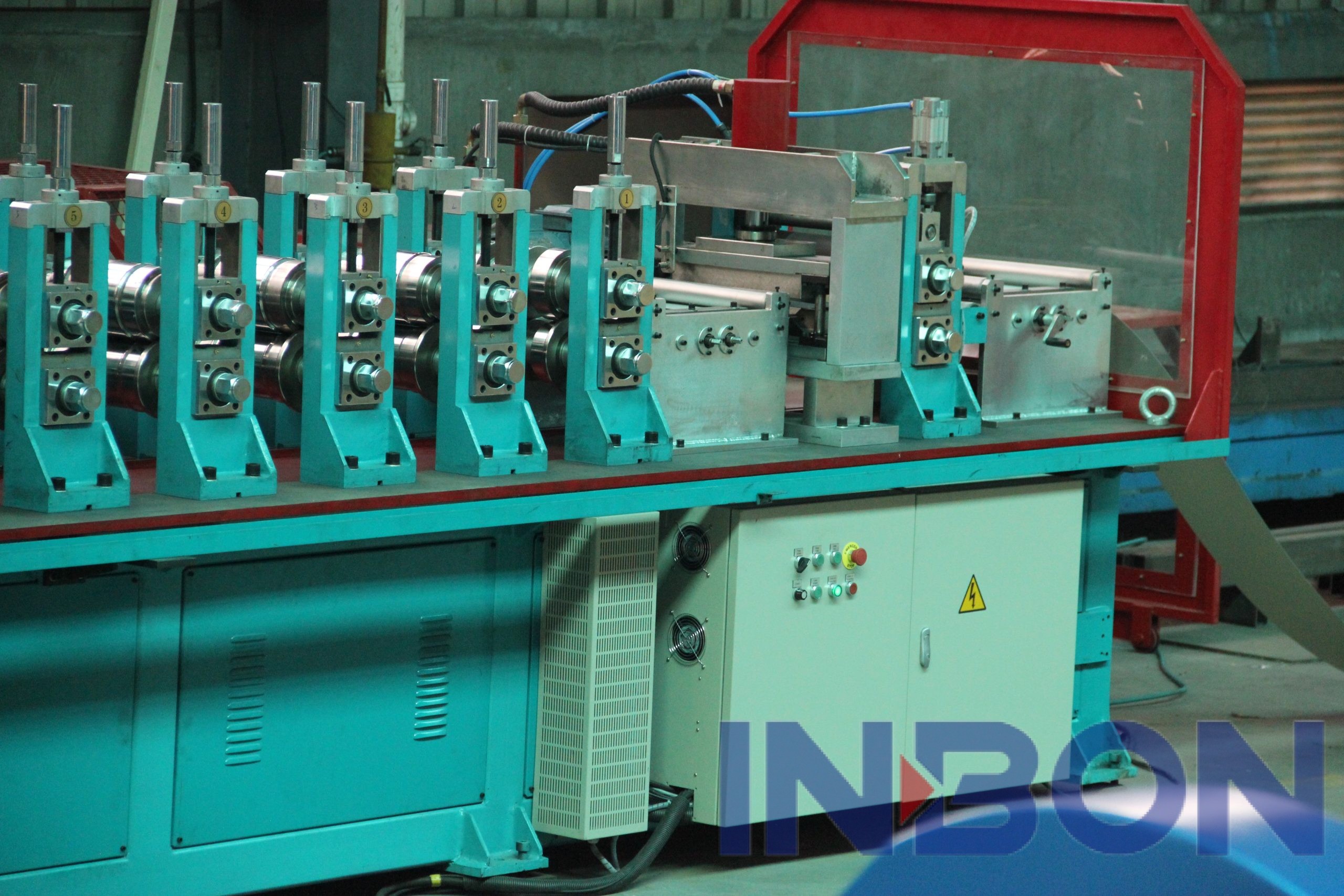

The sealed beam roll forming machine has a frame that supports the rollers and provides stability to the machine. The rollers are arranged in a series of stations, each designed to perform a specific operation on the sheet metal. As the sheet metal passes through the machine, it is gradually bent and shaped into the desired profile.

The sealed beam roll forming machine has a number of advantages over other metal forming processes. It is capable of producing high-quality, precision-shaped parts efficiently and cost-effectively. The process can be easily automated, reducing labor costs and increasing production rates. Additionally, the sealed beam roll forming machine can be used to form different types of sheet metal, making it versatile and suitable for various applications.

In conclusion, the sealed beam roll forming machine is a powerful and versatile tool for shaping sheet metal into desired profiles. It offers efficient, cost-effective production of high-quality parts, making it suitable for a variety of industrial applications.