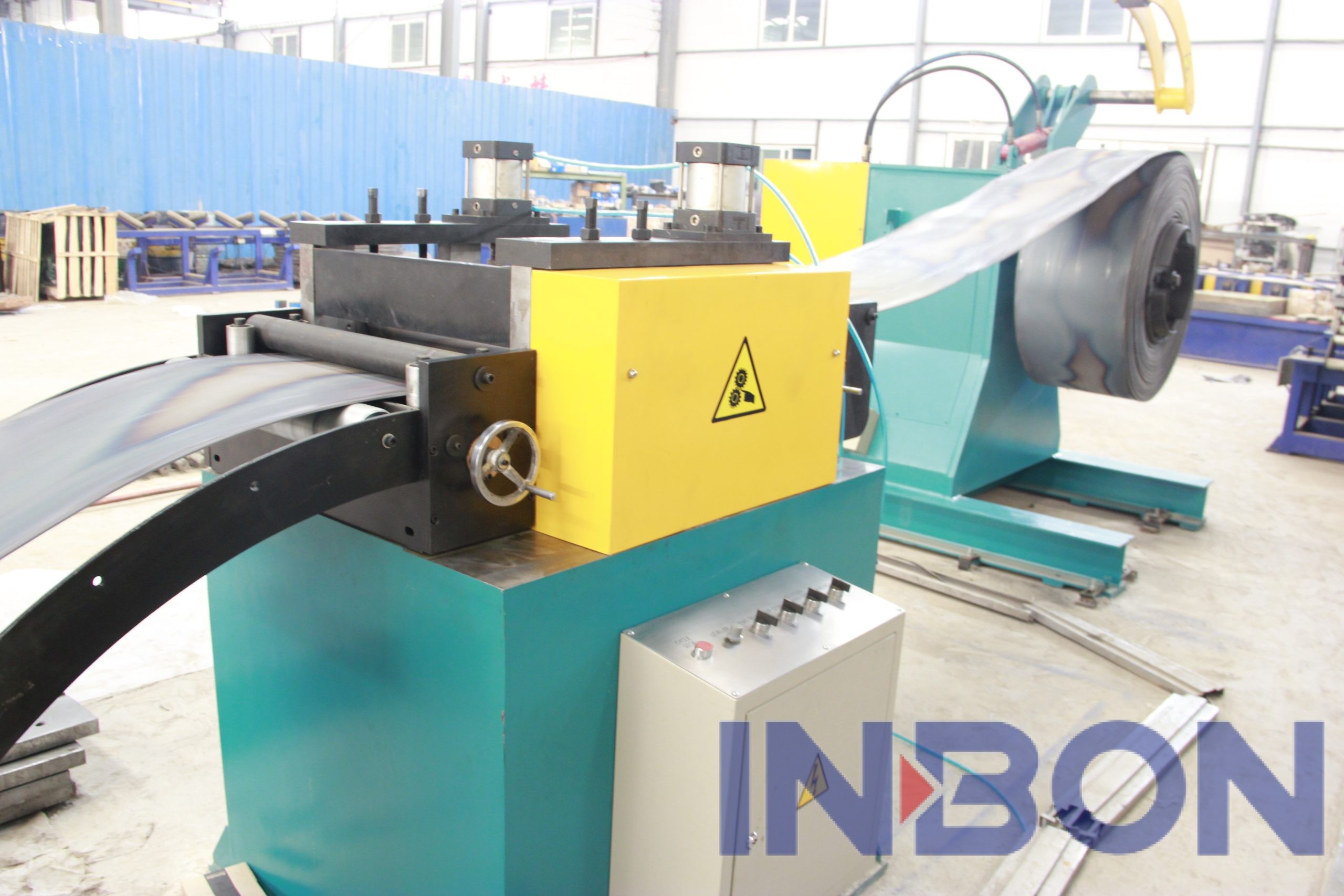

The flattener for the roll forming machine is a crucial component in ensuring the quality of the final product. Its main function is to flatten and straighten the sheet metal as it passes through the roll forming machine, correcting any bending or warping that may occur during the manufacturing process.

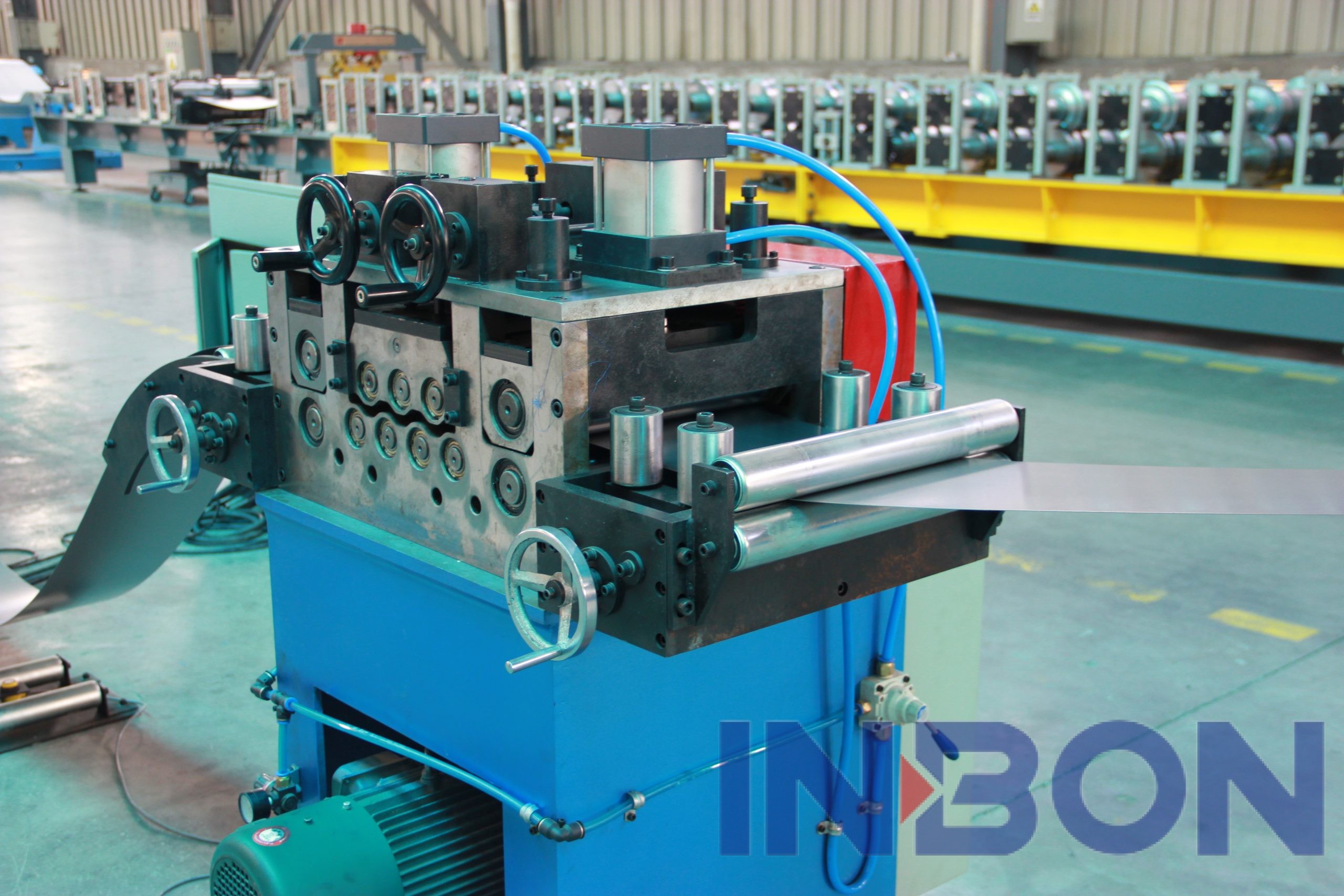

The flattener is typically installed after the roll forming stage, where it applies pressure to the sheet metal, forcing it to conform to the desired shape. The flattener uses a series of rollers that apply controlled force to different parts of the sheet, ensuring that it is evenly straightened and flattened.

The flattener for the roll forming machine offers several advantages:

Improved Flatness: The flattener ensures that the sheet metal is completely flat, meeting the required standards for flatness, thickness, and surface finish. This improves the quality of the final product and reduces the need for further processing or finishing steps.

Consistent Results: The flattener provides consistent and repeatable results, ensuring that each sheet metal piece is treated equally and meets the required quality standards. This reduces variations in the final product and increases productivity.

In conclusion, the flattener for the roll forming machine is a crucial component in ensuring the quality of sheet metal products. It provides superior flatness, consistent results, efficient operation, and customizability for different applications, helping manufacturers to produce high-quality products efficiently.